Solving the Toughest Industrial Challenges

Tikomp empowers manufacturers to overcome production bottlenecks and achieve precision outcomes that others can't match

Complex Production Challenges

We tackle forging and cold plastic deformation processes that most manufacturers avoid.

Scaling Without Compromise

From prototypes to full production runs, we deliver speed, reliability, and flexibility.

High Precision Requirements

Our technological solutions deliver high reliability and excellent mechanical properties as well as very high precision.

Durability Under Pressure

Components engineered for extreme wear, load, and operational demands.

Our Expertise

Cold Plastic deformation

The main advantage of cold plastic deformation is in both savings of raw material and the ability to process small-sized components. This also defines the main trend in modern metal-working.

By applying cold plastic deformation, we are able to produce components with excellent mechanical properties and microstructure, which makes them durable enough to sustain large alternating loads.

Hot forging and press forging

By using Hot Forging and Press Forging technologies we process various components made of ferrous and non-ferrous metals and alloys.

We can achieve high productivity, very good micro-structure and mechanical properties, very accurate finish of external and internal surfaces either of regular or irregular shapes, thus reducing subsequent machining.

metalworking

We provide metalworking services alone or combined with preliminary plastically deformed components.

We develop appropriate technological regimes and we use modern wear-resistant tools, which increase productivity and reduce product cost.

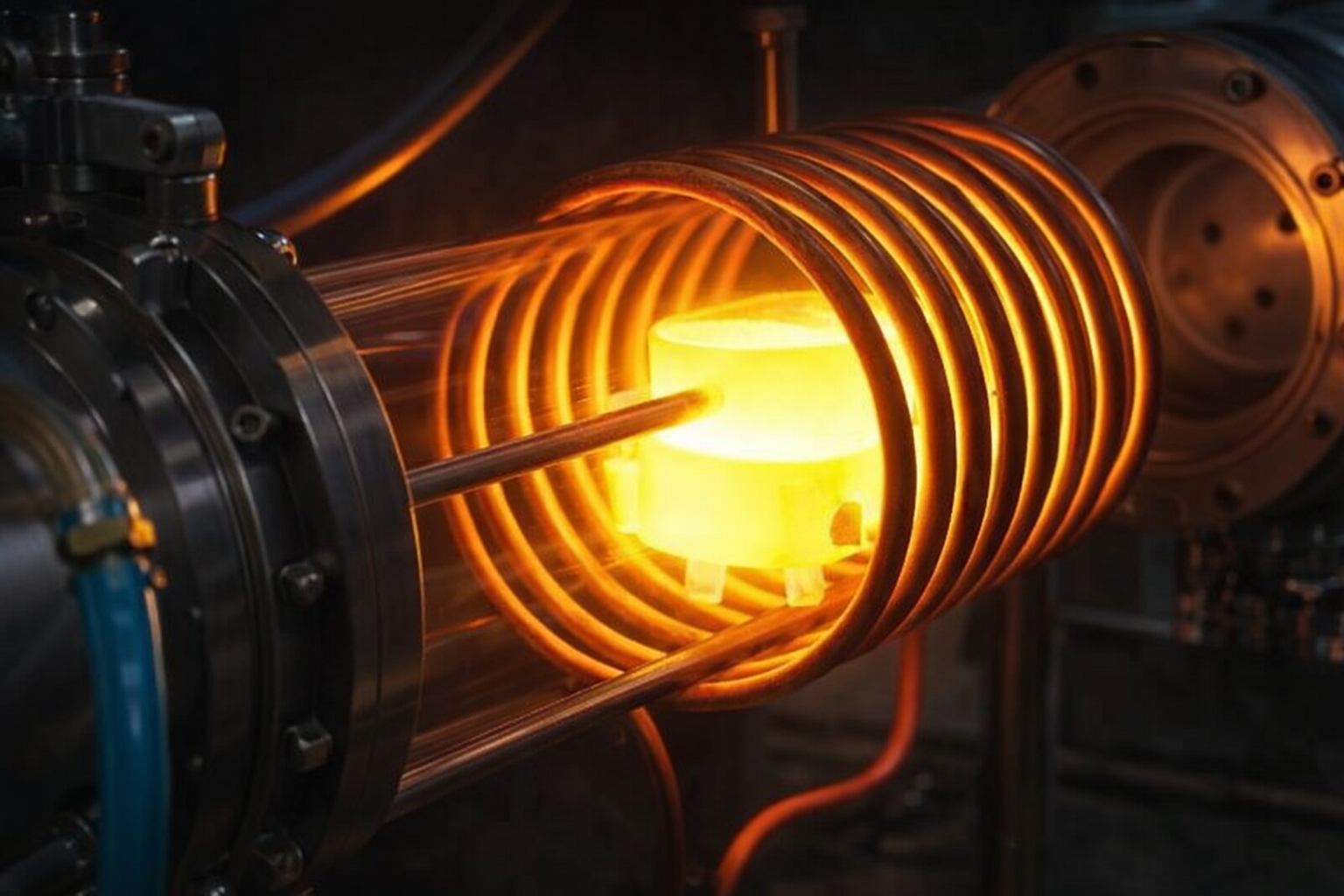

Induction hardening

Based on methods developed for inducing high frequency current followed by cooling, we can achieve much better material characteristics than those achieved by the traditional hardening techniques.

As a result, Rockwell hardness (HRC) could be 4-6 units higher than obtained by standard methods.

Technical capabilities

Materials

We specialize in the forming and processing of ferrous and non-ferrous metals, with deep process knowledge in the materials listed below.

Ferrous metals:

Cast iron and steel

Non-Ferrous metals:

Nickel-based alloys, aluminium, copper, duralumin, bronze.

This overview reflects our most commonly used materials.

If your application requires other material qualities or alloys, contact us. We regularly adapt processes to meet specific requirements.

component size range

We are optimised for small to medium-sized components, typically ranging from a few centimetres up to approximately 30cm.

This specialisation enables superior control of:

Grain flow

Dimensional accuracy

Mechanical properties

For more examples, visit our portfolio page.

However, larger components can also be produced in cooperation with our forging partner, allowing us to extend capacity without compromising quality control.

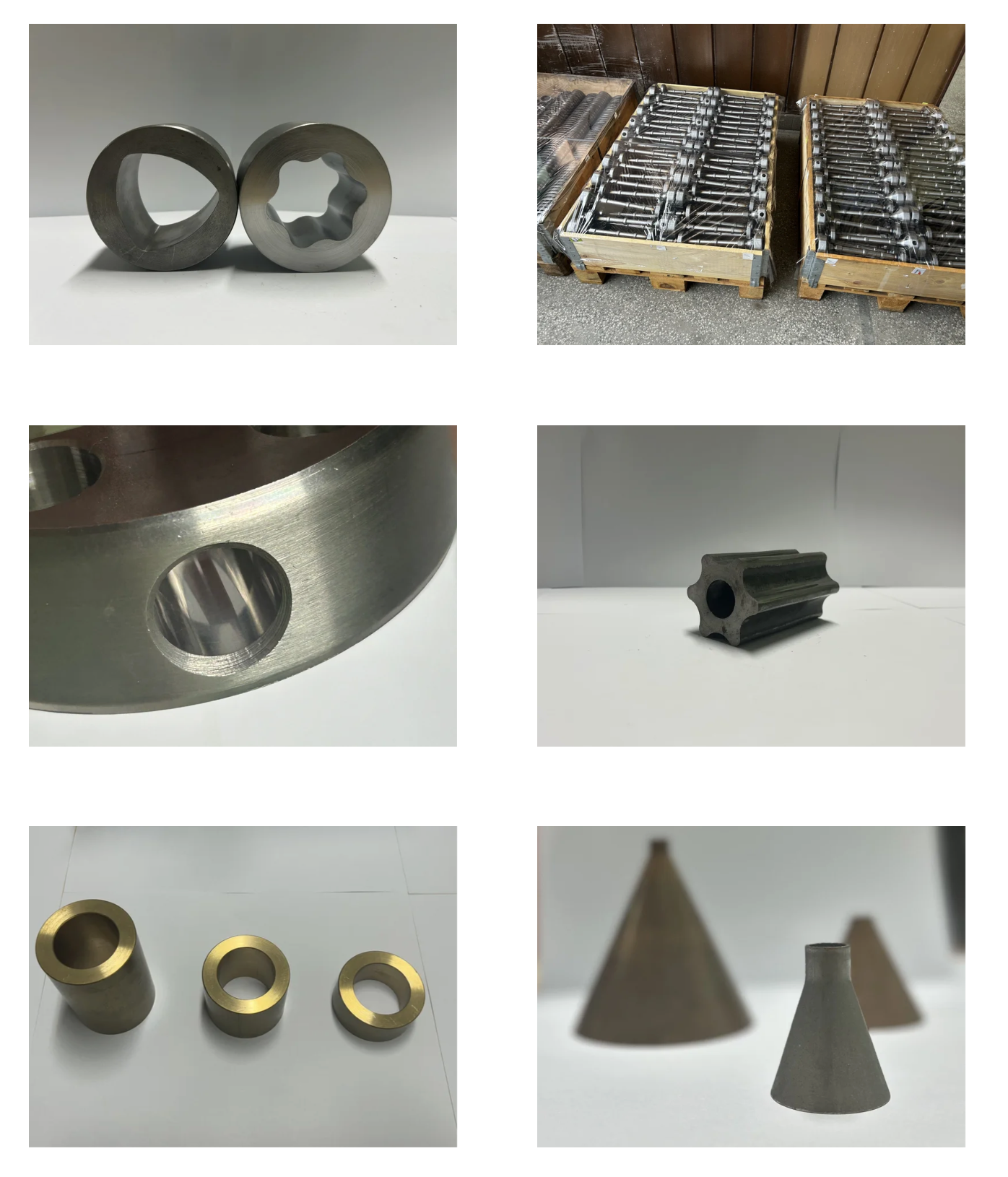

Shapes & Geometry

Rings

Precision-machined rings with tight tolerances and clean chamfers for load distribution, sealing, or spacing.

Discs

Solid metal disks with controlled thickness and flatness for structural or wear applications.

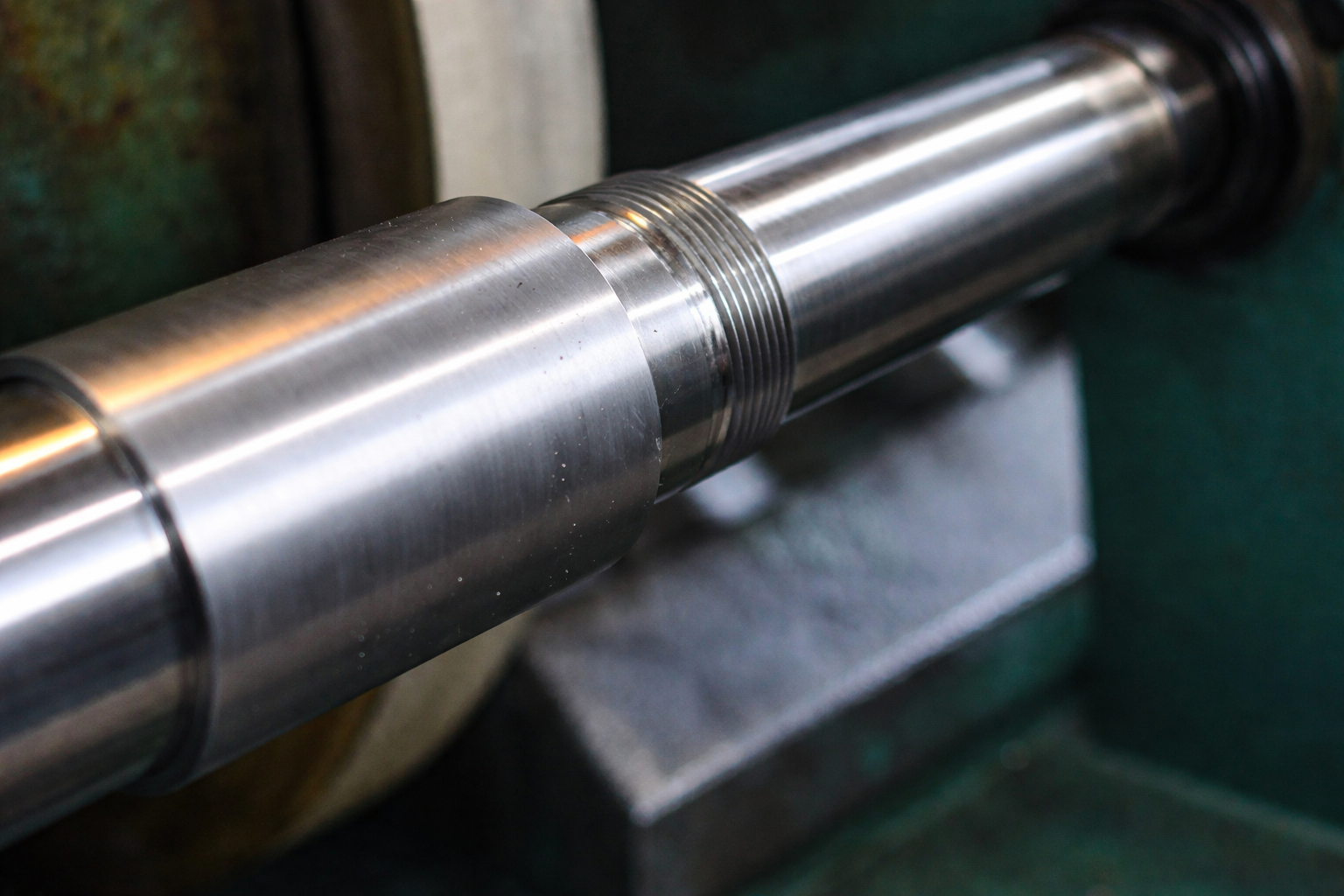

shafts

Stepped, grooved shafts engineered for accurate alignment and torque transmission.

Special shapes

Custom, non-standard geometries designed and manufactured to meet complex functional requirements.

Our forming technologies are designed to achieve:

Significant material savings

Enhanced mechanical properties, usually 2–3× stronger than components produced with conventional methods, depending on application

To see more of our work, check our portfolio page.

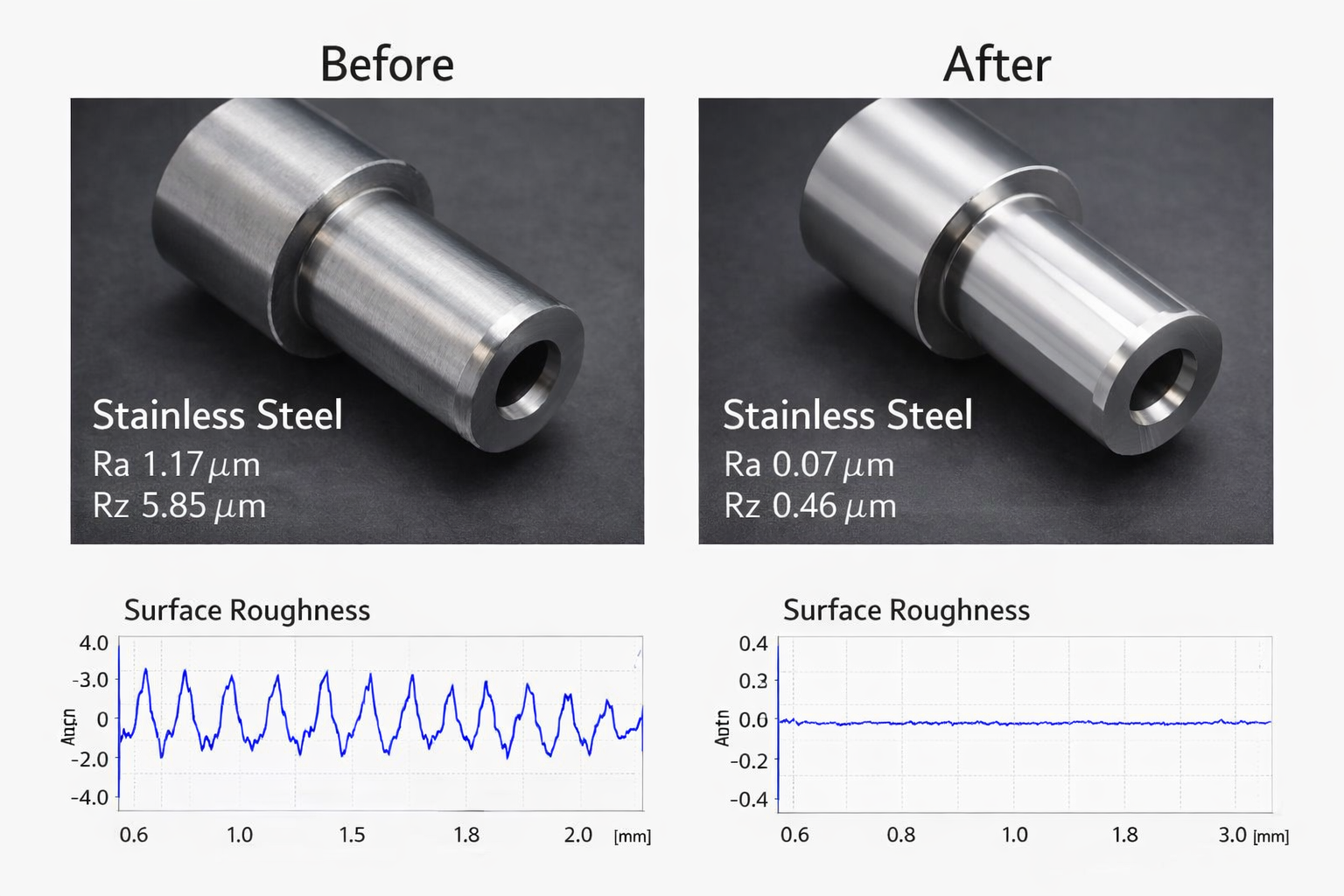

Tolerances

Using our burnishing technologies, we achieve:

Precision up to 1/100 of a micron

Accuracy independent of component size or geometry

This level of precision is consistent and repeatable, making it suitable for series production of high-performance components.

Batch sizes

We support production across the full range:

Pilot and pre-series runs

Medium series

Large-scale production

Minimum order quantities depend on component specifications, material, and processing requirements.

Contact us to determine the MOQ for your project.

Additional Processing

When required, we apply additional processing to further improve performance and service life.

Heat treatment

Controlled heating and cooling used to adjust a metal’s strength, hardness, and durability.

Burnishing

A finishing process that smooths and hardens the surface by plastic deformation, without material removal.

mechanical machining

Material removal using cutting tools to achieve precise dimensions and complex geometries.

Each process chain is selected case-by-case, based on material, geometry, and operating conditions.