How we work: From Concept to Series Production

Our process is designed to minimize risk, ensure technical correctness, and scale reliably.

Phase i: Engineering & Solution Design

You provide the drawings and technical requirements.

We then:

Analyse the component and its application

Select the optimal manufacturing technology

Perform engineering calculations

Propose the most efficient and reliable solution

Phase ii: Test Run & Validation

Pilot production

Process validation

Fine-tuning before scale-up

This phase ensures that geometry, tolerances, and mechanical properties are fully validated before series production.

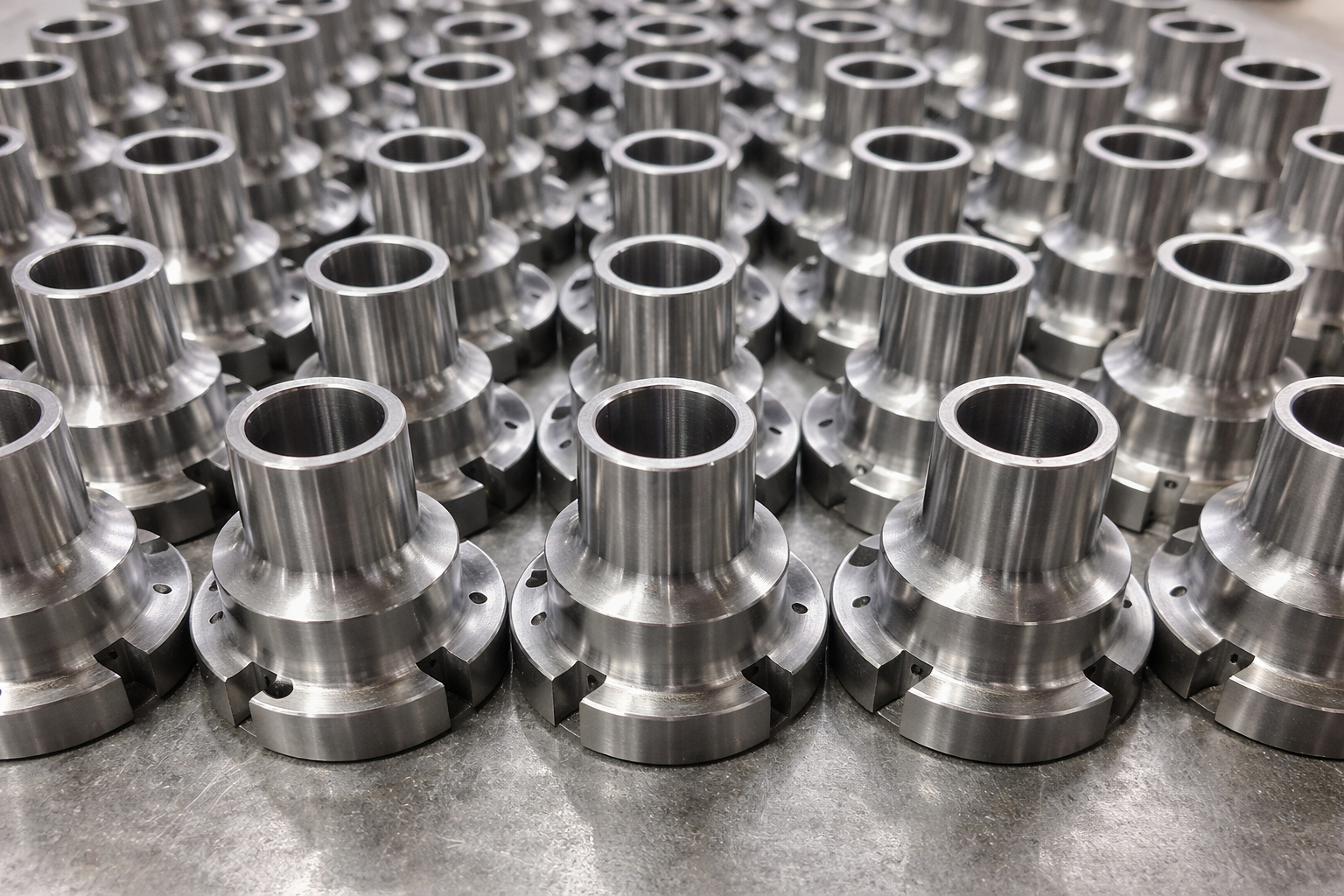

phase iii: Series & Mass Production

Gradual ramp-up

Stable, repeatable output

Long-term production partnership

New clients typically begin with smaller runs and scale production once results are validated.

Information Required from Clients

The quality of input directly affects the quality of the final component.

We recommend providing:

Drawings and tolerances

Material specifications

Mechanical requirements

Application details, including:

Continuous or periodic load

High-stress or low-stress environment

This information allows us to optimise strength, cost, and longevity.

Timelines

Lead times depend on component complexity:

Existing or simple components: typically a few weeks

New or high-know-how components: longer development cycles

Additional time is an investment: it ensures correctness, durability, and consistent performance over the component’s full lifecycle.

intellectual property

When a project requires non-standard solutions and significant engineering know-how:

We consult patent specialists

Novel solutions are patented when appropriate

Your innovation is protected and our expertise remains defensible.